Zamak die-casting

Zamak die-casting makes possible to produce items with great finishings and lower limits of tolerances.

Zamak die-casting makes possible to produce items with great finishings and lower limits of tolerances. Moreover, the molds used for Zamak manufacturing last more than the ones used for other alloys.

Zamak is cheaper and lighter than brass. With Zamak die-casting it is possible to realize items with complex forms, sich as thinner walls, holes or thornes, with no need of further expensive and difficult handmade corrections.

What is Zamak?

Zamak is a zinc alloy with great electrical and thermic conductivity, mechanical resistance and hardness, high stability and the possibility to create thin thicknesses.

Zamak is an alloy which guarantees great performances in any galvanic treatment, such as chrome, zinc, gild, nickel and copper plating.

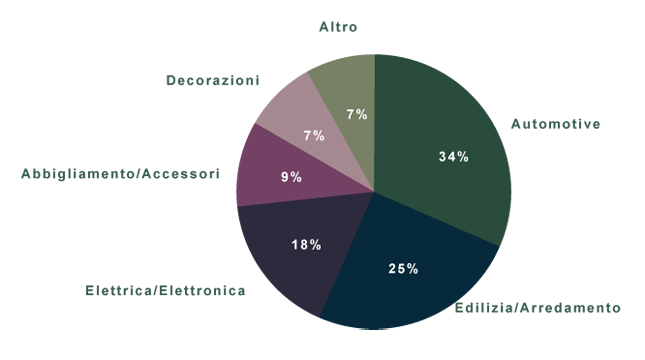

Zamak is used in many production sectors

- Automotive: zamak is used for the production of many car components, such as carburators, locks, antennas and electrical and mechanical inner components;

- Construction industry and furniture: hinges, switch plates, handles, drawer mechanisms, fasterners, locks and roller shutters;

- Electrical and electronic industry: inner components of computer and mobile phones, electrical engines and electronic devices;

- Apparel and accessories: belt bucklers, zippers, buttons, metallic decorations on shoes, leather items and apparel;

- Decorations: friezes, promotional and design items;

Environmentally friendly

Zamak respects the environment. Zamak manufacturing requires less energy than similar materials;

moreover, it can be completely recycled.

Would you like a free quote?

Fill in the form and you will be contacted